Clutch kit

More powerful engines, longer ratios and new lifetime specifications have led to the development and introduction of more complex clutch designs such as Valeo SAT (Self Adjusting Technology). The SAT is a Valeo revolutionary technology that uses a self-adjusting facing wear compensation device on the pressure plate, thereby enhancing the clutch life and improving the pedal comfort. Valeo also supplies its self-adjusting technology to truck manufacturers.

As an aftermarket solution provider, Valeo engineers have designed a new clutch kit named HEC (High Efficiency Clutch) to replace the competitors’ self-adjusting clutch and give full satisfaction in terms of quality, reliability and durability. This is done by using an improved cover assembly and a low-wear facing (range from 190 mm to 260 mm), resulting from years of research in Valeo’s R&D centers. This solution does not require a specialist tool, which facilitates the fitting operations.

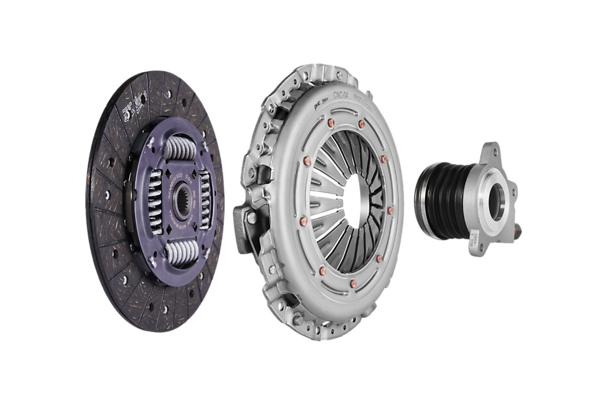

Today, over 3,400 part numbers (kits and components) cover 91% of the total car range, with a major presence within all major car makers such as French, German, Korean, Japanese, Italian manufacturers. Choose Valeo A wide Traditional clutch kits range :

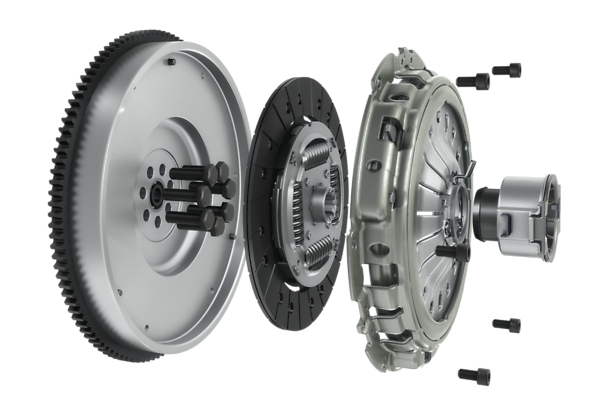

- 3PKIT including concentric slave cylinder (CSC): 100 part numbers available

- Self adjusting technology (SAT): 205 part numbers available of which high efficiency clutch (HEC): 65 part numbers available

- CV clutches: 700 part numbers available of which 100 part numbers are remanufactured

An expanding offer for Korean and Japanese car application : Valeo provides large business opportunities with Asian applications. With the same level of quality and services as Valeo’s other ranges. Valeo is investing in all product lines to vastly extend its offer for Korean and Japanese vehicles and help you to rationalize your sourcing. Thanks to the range including over 670 kit part numbers, Valeo's estimated Asian car range coverage is now at 80%. New references include mainly traditional clutch kits and cover all vehicle generations. Some well-known applications are available for Hyundai Accent, Nissan Micra, Daewoo Matiz, Suzuki Grand Vitara and Toyota Aygo & Yaris and many more.

Major expertise : Reman range for Commercial Vehicles Valeo remanufactures the Commercial Vehicles clutch kit especially the large diameter over 330 mm. The remanufacturing process is integrated into our facility that assembles the OE clutch kits. Having implemented an efficient collection process all over Europe, Valeo is able to get the cores from all its customers and to help to save up to 50 kilos of raw material per kit (up to 90 kilos for twin disc kits). After collection, all the cores are sorted, dismantled and cleaned, and, before the re-assembling in the production line, the components are submitted to test on benches. The Reman process strictly fulfills the same specifications set for OE.

Discover Valeo's clutch system e-learning on www.valeo-techassist.com