Egr exchanger

The EGR system emerged with the increase of HDI applications and a new European regulation to reduce pollutant emissions.

The Exhaust Gas Recirculation (EGR) is an efficient, cost-effective system for reducing NOx. The high-pressure EGR loop collects part of the exhaust gases at the cylinder head outlet and re-injects them into the engine air intake. The main benefit is that NOx is reduced at the source by limiting their quantities produced during the combustion process, rather than by post-treating the exhaust gases. The EGR cooler cools the exhaust gases before they enter the engine in order to improve temperature management.

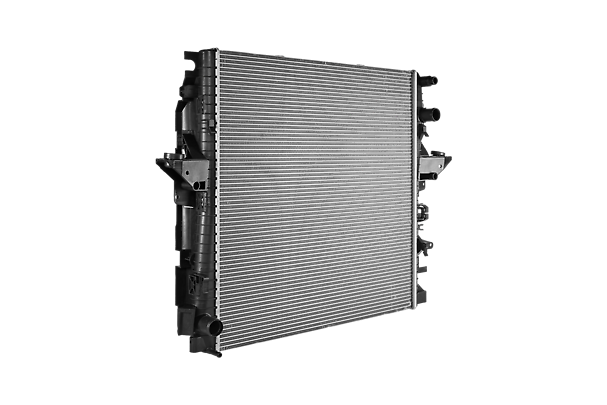

It cools the exhaust gas prior to gas being reintroduced into the engine. The heat exchanger is a gas / water type and can be located upstream or downstream of the EGR.

By cooling the gas the combustion temperature is reduced and the quantity of NOX particles also drops, as they are formed at higher temperatures. The EGR cooler is located beside the exhaust gas manifold of engine. The exhaust gas cooler is a heat exchanger installed in the EGR circuit. By cooling the EGR gas, the volumetric conflict with inlet air can be minimised (EGR cooling allows the increase of the EGR level in mass, and not in volume). The subsequent air-fuel mixture temperature reduction also reduces flame temperature.

As a leader in this field, Valeo has a complete range of competitive solutions based on high and low pressure architectures for petrol and diesel engines. With over 20 years of experience in developing EGR modules, Valeo covers all European emission standards: from Euro2 to Euro6, and proposes a full 100% O.E. quality range covering 16 car-manufacturers. High technology and performing materials are key for Valeo, the only supplier of full EGR systems (including the valve and heat exchanger.)